A sanding disk with rotational inertia is an essential tool in the realm of surface finishing, offering unparalleled precision and efficiency. Its unique characteristics, stemming from the interplay between rotational inertia and sanding dynamics, have revolutionized the sanding process.

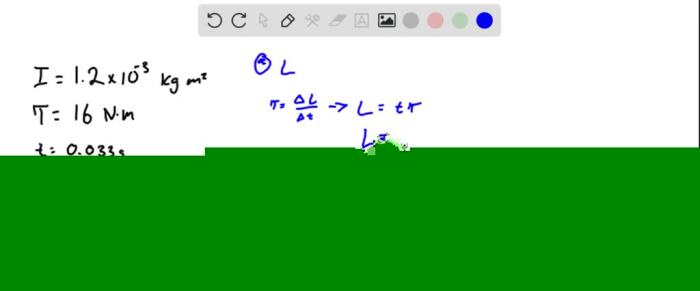

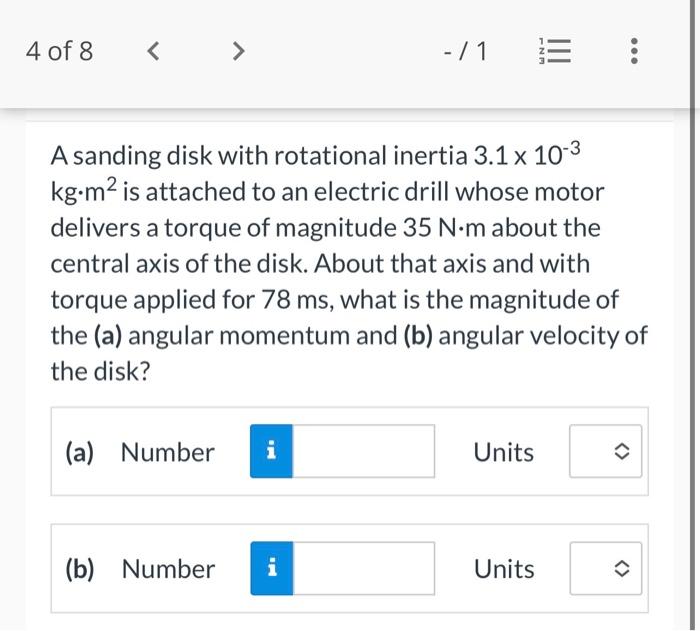

Rotational inertia, a measure of an object’s resistance to angular acceleration, plays a pivotal role in determining the sanding disk’s performance. By understanding the intricate relationship between rotational inertia and sanding speed, users can optimize their sanding operations for exceptional results.

Defining Rotational Inertia: A Sanding Disk With Rotational Inertia

Rotational inertia, also known as moment of inertia, is a physical property of an object that measures its resistance to angular acceleration. It quantifies the distribution of mass around an axis of rotation.The formula for calculating rotational inertia (I) for a rigid body rotating about a fixed axis is given by:“`I = Σ(mr²)“`where:

- m is the mass of an infinitesimal element of the body

- r is the distance from the element to the axis of rotation

Sanding Disk Properties

Sanding disks are typically made of abrasive materials such as aluminum oxide, silicon carbide, or ceramic. The grit of the disk refers to the size of the abrasive particles, with higher grits indicating finer particles. Common grit sizes range from 36 (coarse) to 1200 (very fine).Disk

thickness also affects performance. Thicker disks provide more stability and durability, while thinner disks are more flexible and conform to curved surfaces better.

Rotational Inertia and Sanding Performance

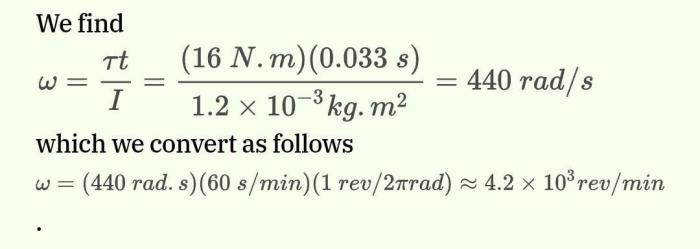

Rotational inertia plays a crucial role in the sanding process. Higher rotational inertia provides more resistance to changes in angular velocity, resulting in smoother and more consistent sanding. This is particularly important for applications where precise control is required, such as fine finishing or shaping.The

relationship between rotational inertia and sanding speed is inversely proportional. Higher rotational inertia requires more torque to achieve the same sanding speed. Therefore, it is important to consider the power of the sanding tool when selecting a disk with appropriate rotational inertia.

Sanding Disk Design Considerations

Sanding disks come in various designs, each with its advantages and disadvantages:

-

-*Flat disks

Provide a uniform sanding surface for flat surfaces.

-*Hook-and-loop disks

Allow for quick and easy attachment and removal.

-*Velcro disks

Similar to hook-and-loop disks, but with a more aggressive grip.

-*Self-adhesive disks

Offer a secure hold but can be more difficult to remove.

The choice of disk design depends on the specific sanding application and the desired level of performance.

Safety Considerations, A sanding disk with rotational inertia

Using sanding disks involves potential hazards, including:

-

-*Dust inhalation

Sanding generates fine dust particles that can be harmful to the respiratory system.

-*Eye injuries

Debris from sanding can cause eye irritation or injury.

-*Skin irritation

Abrasive particles can cause skin irritation or cuts.

To minimize risks, it is essential to wear proper safety gear such as a respirator, safety glasses, and gloves. Additionally, the sanding area should be well-ventilated to prevent dust accumulation.

FAQ Resource

What is the significance of rotational inertia in sanding?

Rotational inertia governs the disk’s ability to maintain a consistent speed during sanding, ensuring smooth and uniform surface removal.

How does disk thickness influence sanding performance?

Thicker disks possess greater rotational inertia, enabling them to withstand higher sanding forces and maintain stability.

What safety precautions should be taken when using sanding disks?

Always wear appropriate safety gear, ensure proper ventilation, and inspect disks for damage before use.